- Cold formed steel framing projects how to#

- Cold formed steel framing projects professional#

- Cold formed steel framing projects series#

Galvanized cold-formed steel offers a unique combination of benefits that set it apart from other framing materials.

Cold formed steel framing projects how to#

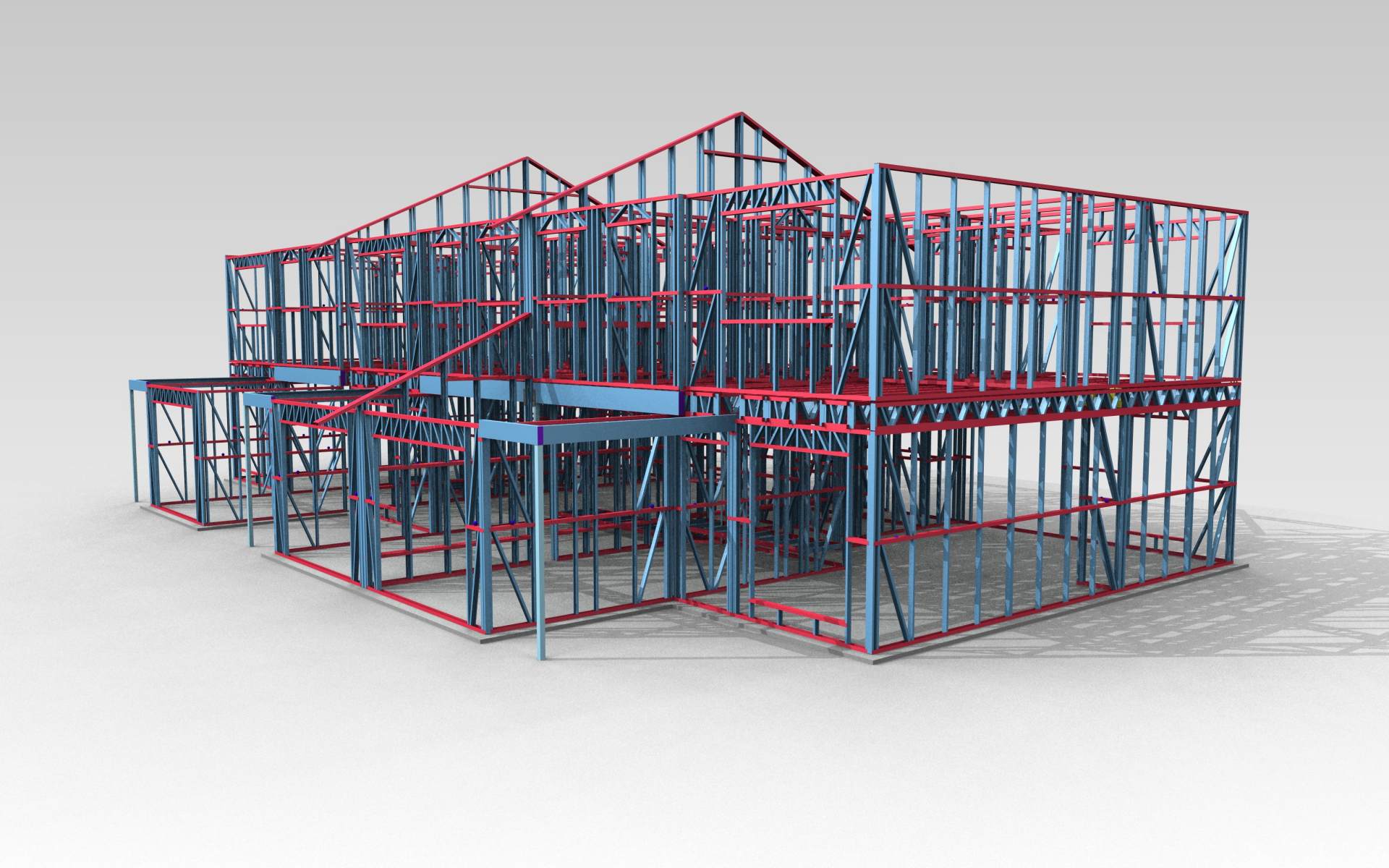

To discuss how to maximize the benefits of cold-formed building components on your project, contact us today! The extreme versatility of cold-formed steel also results in building components that are ideal for use in combination with alternate construction systems. Our team can offer turn-key framing solutions for any application and to date, our systems have been utilized in complete structures such as hotels, condominiums, long term care facilities, high-end single family homes, restaurants, water/sewage treatment plants, storage facilities and multi-residential buildings up to six stories high. Construction projects ranging from commercial, industrial, residential, retail and agricultural end uses can be completely framed using cold-formed framing solutions provided by VanderWal Homes & Commercial Group Inc. The numerous advantages of cold-formed steel components make it the ideal framing material to be used across a wide variety of building types and applications. is able to deliver products that are the best long-term investment for all of their clients. By using materials manufactured for superior consistency and a fabrication process focused on quality, VanderWal Homes & Commercial Group Inc. We are dedicated to improving the construction experience of each of our clients. continually works to supply the most cost-effective and efficient building solutions while not compromising on our dedication to high quality of workmanship. Prefabricated cold-formed steel framing components can reduce installation time by up to 75% and can eliminate the need for multiple on-site trades/labour. Cold-formed steel components are manufactured to the exacting standards and with the precision required by the most sophisticated modern construction projects. is the construction industry's leading supplier of specialized steel structures. With a state-of-the-art fabrication facility and a focus on delivering the highest quality pre-engineered components, VanderWal Homes & Commercial Group Inc. strives to maintain nationwide presence and is in an unrivalled position to deliver to any location in Canada. Our team is dedicated to providing the highest quality Cold-Formed Steel (CFS) framing solutions in the form of CFS Truss Framing Packages, CFS Floor Framing Packages, CFS Panelized Wall Framing Packages, and CFS Construction Accessories.

Cold formed steel framing projects professional#

Our team consists of professional designers and construction experts who thrive on developing framing and building solutions that can be adapted and customized to fit any building project. is Canada's leading structural Cold-Formed Steel specialist with over 15 years of experience in the design and fabrication of cold-formed steel components. Finally, design recommendations for seismic design of light gauge steel framed buildings were given for practical design.VanderWal Homes & Commercial Group Inc. These models were used for parametric studies which allowed analytical formulae for calculating the Q factor to be acquired. Two hysteretic modelling alternatives for shear walls have been developed in the project. The Q factor takes into account non-linear behaviour of the structure and makes it possible to apply elastic design. One main goal of the project was to determine the Q factor for LGS structures. Several shear wall tests were performed by using different bracing methods in order to find out hysteretic behaviour and other parameters needed in seismic design.

Cold formed steel framing projects series#

The research consisted of comprehensive connection test series for steel plate connections and test series for sub-assemblies for different shear wall corner configurations. The main strategy in the shear wall design is to design the bracing system as dissipative elements and design studs and tracks and other load-bearing elements to behave elastically with adequate overstrength. Typical bracing methods that are also covered in this research are X-bracings with diagonal steel straps, sheeting of plane steel sheets or gypsum- or wood-based wallboards. The proposed methods are directly applicable in low seismicity areas defined in Eurocode 8, but can also be utilised in higher seismicity areas, it the structural applications with all details are verified by testing, for example, according to this document. The scope of the project was limited to one- or two-storey buildings with load-bearing stud walls made of cold-formed steel profiles. Seismic design methods for light gauge steel framed buildings have been developed in this project.

0 kommentar(er)

0 kommentar(er)